We process metals using the most advanced technologies and methods in the industry. We are certified with EN ISO 9001, EN ISO 3834-2, EN ISO 15085-2 CL1, and ČD V95/5. This enables us to create products you won’t find anywhere else on the market.

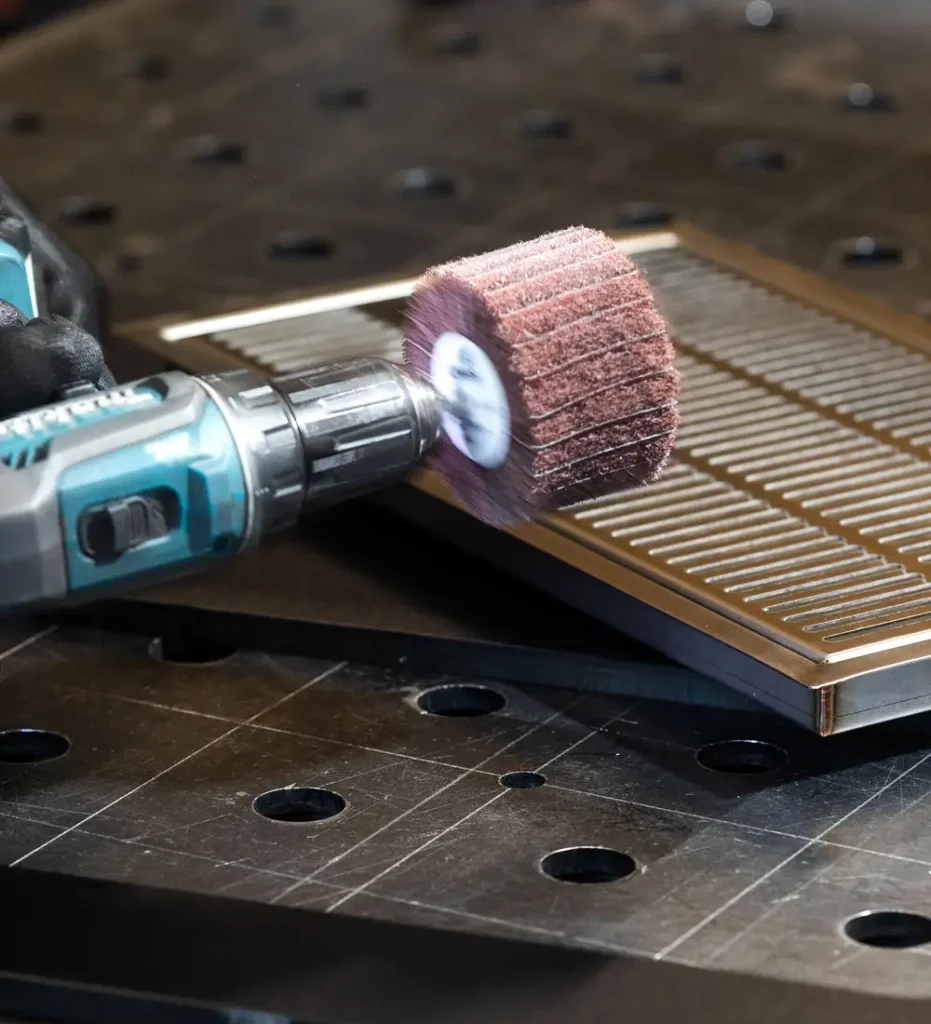

We specialize in welding stainless steel, carbon steel, and aluminum. We are experienced in TIG, MIG/MAG, and point welding methods. With high-quality tools for grinding, our products meet the highest standards of quality.

We use the latest software to bring your ideas to life. We offer 3D model creation, rendering, and standardized technical documentation. Throughout the entire process, we remain in constant contact with you.

We bend pipes with diameters of 25×1.5, 30×3, and 31.8×3.2, as well as steel bars with diameters of 25x25x1.5. The maximum length is 6,000 mm. Our new-generation machines ensure maximum precision and allow for the creation of almost any shape.

Our high-performance gravity band saw offers a wide range of angular cuts with infinitely adjustable control. Precise blade guidance ensures an accurate cut. The saw is equipped with a roller feeder for cutting blanks up to 7,000 mm in length.

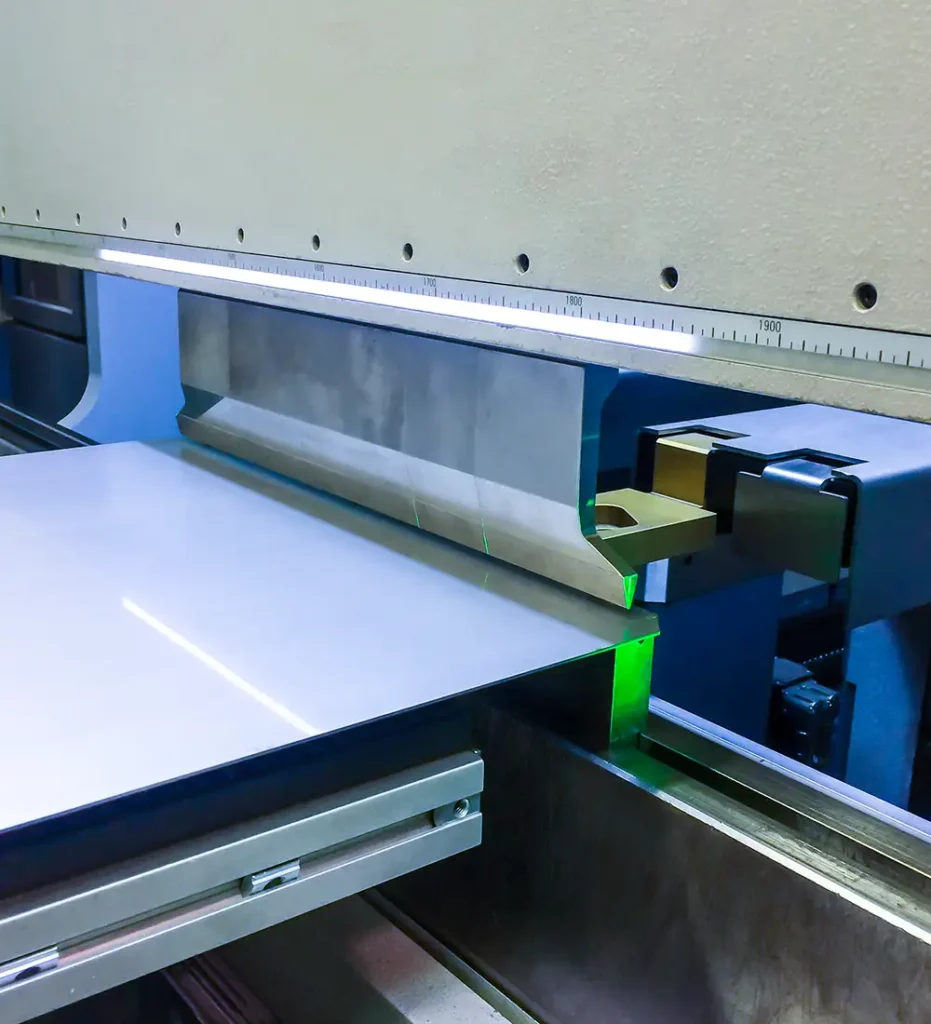

Sheet metal bending is a fundamental process in metal processing, and we use CNC bending machines and presses to perform it. We bend sheet metal up to a length of 3,000 mm, depending on its thickness. We can also create edge moldings up to a maximum thickness of 1.5 mm and a length of 2,000 mm.

We use laser cutting to achieve clean, precise results while protecting the material. We can handle maximum dimensions of 3,000×1,500 mm. For stainless steel grade 17, we cut up to a thickness of 10 mm, for common steel grade 11 up to 20 mm, and for aluminum up to 10 mm. Other steel types are cut based on individual requirements.

We apply varnish to materials, ensuring resistance to moisture and UV radiation while achieving the desired appearance. This method is suitable for both interior and exterior use. We have a wet paint shop and can handle blanks up to 6,000×3,000 mm in size.

This popular machining method uses a rotating tool to remove material from the workpiece, allowing for precise shaping and the creation of various details and surface types. We offer four-axis milling for blanks with maximum dimensions of 500x400x300 mm.

Beveling is the process of cutting edges at specific angles, making it easier to join materials, such as in welding. We perform beveling at 45° and 50° angles, up to a depth of 5 mm. This method is suitable for demanding industrial applications.

Our additional finishes enhance the appearance and durability of stainless steel materials, providing protection against corrosion and extending surface life. We perform grinding and cleaning to give stainless steel functionality for a wide range of applications.

We handle a variety of methods for modifying stainless and conventional steel, including drilling, countersinking, threading, roughing, and reinforcing. Based on your requirements, we will determine the best process and get to work.

Are you considering using our services? Fill out our contact, and we will get in touch to find the right solution for your needs.

Okružní 757, Č. Budějovice

Okružní 757, Č. Budějovice